Product Design 产品设计

Led by international, industry renowned creative teams, Xinyu’s Design Services offers customers the finest, most intuitive innovation and design input for skincare, color cosmetics, perfume and spirits packaging

Design teams are fully integrated within Xinyu global sales offices and manufacturing facilities, ensuring access to the industry’s most advanced technology and our exemplary engineering and project management support; from concept sketch right through to industrial realization.

The Xinyu design team is here to help generate amazing customer experiences that build success for all brands.

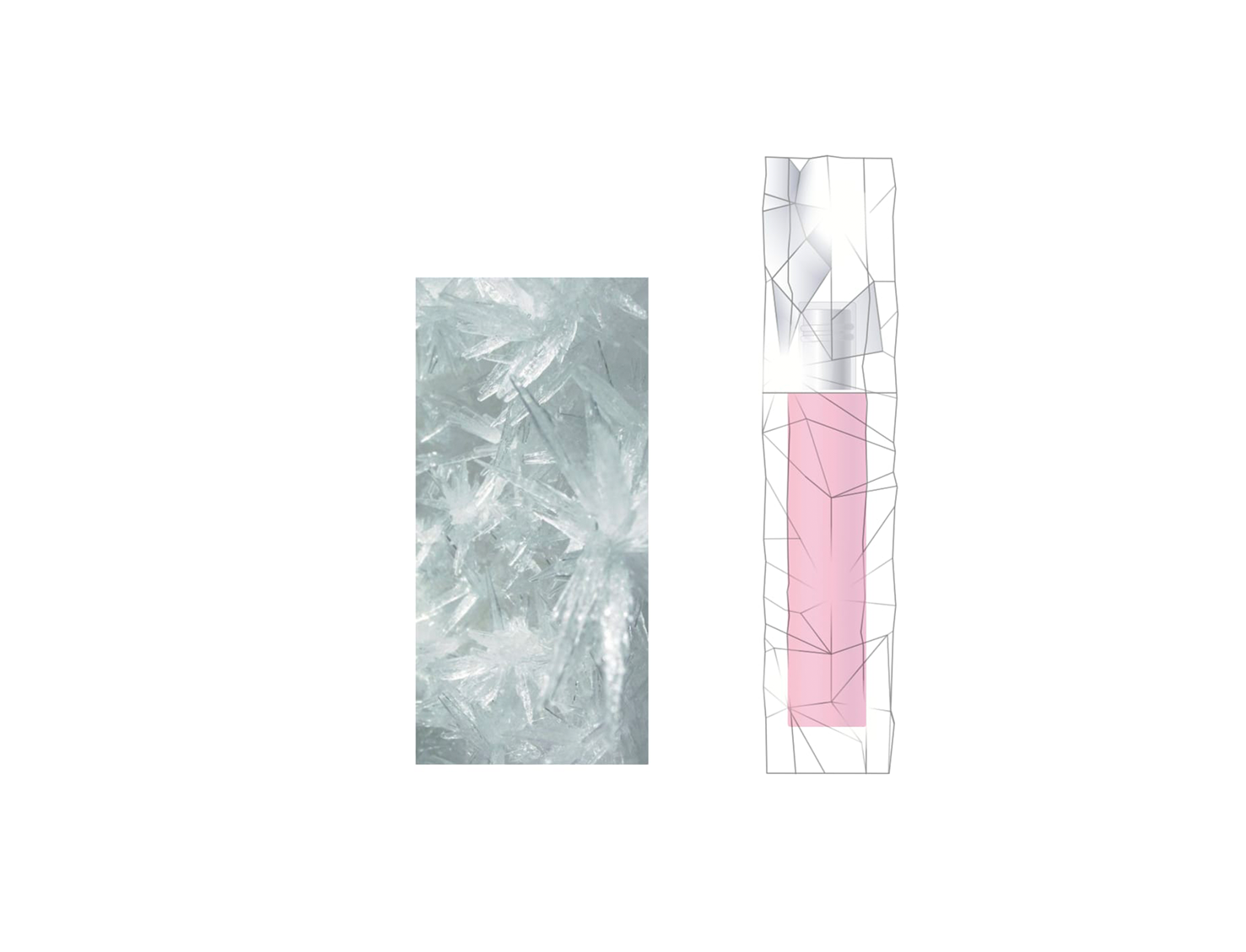

Materials Selection 材料选型

Balancing the Brands. vision with package compatibility can have a large impact on the materials used for your package. We offer a wide range of materials that can be used in-stock packages from plastic, PCR, glass, aluminum and bamboo as examples, and we are happy to consult and provide guidance on material selection & decoration based on your Brands needs.

Not sure what materials to use? Contact us here, our engineering experts can help advise you.

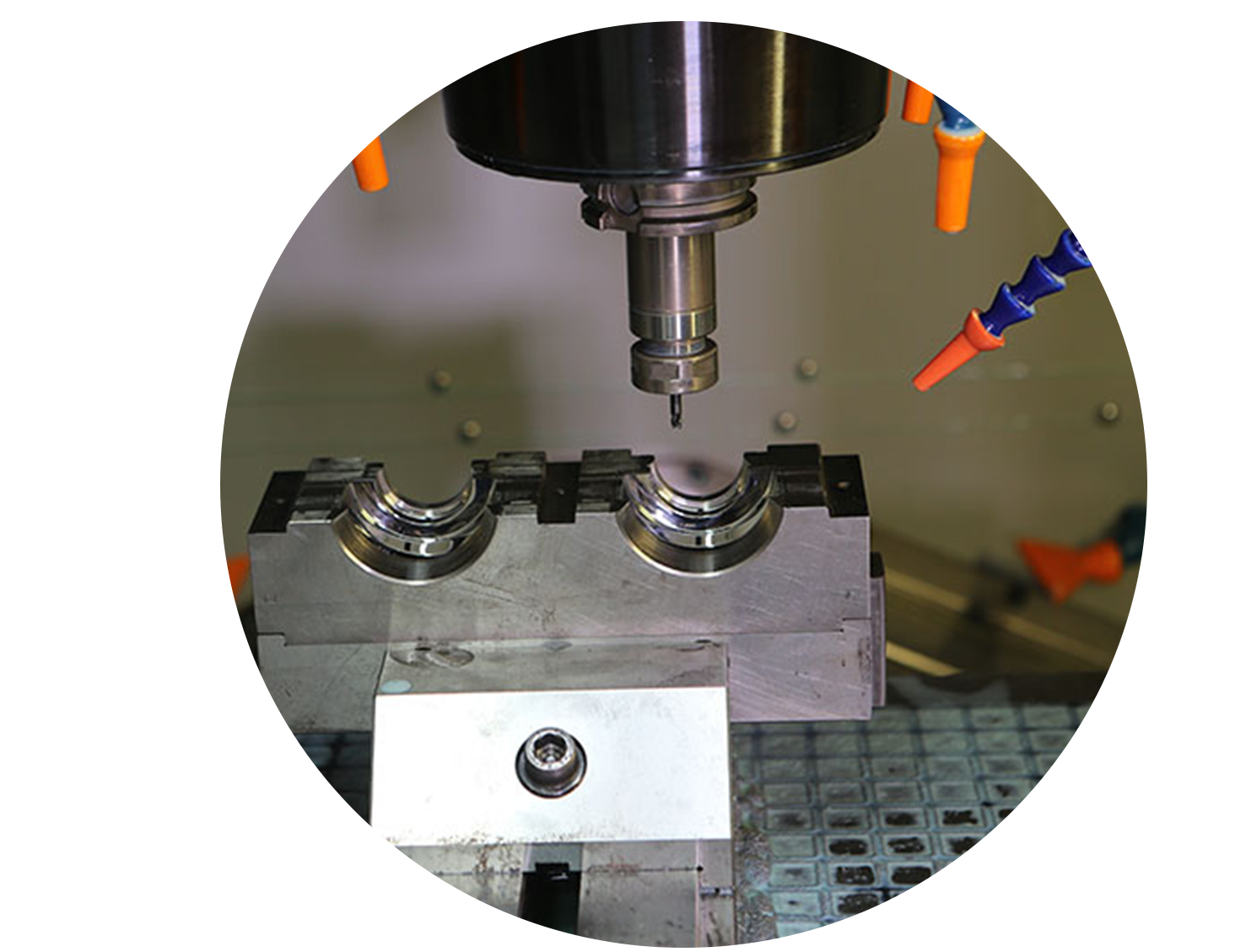

Moulding Workshop 模具设计制作

Annually, more than 400 sets of injection moulds are developed.

Services include mould design and mould development and production.

Lead time for Injection/glass bottle mould production: 4 weeks.

Top manufacturing and testing equipment from Germany and Japan are used.

Cold runner, hot runner or semi-hot runner is provided according to different projects

Mould technological process is combined with precise system control

Injection Workshop 注塑成型

Daily capacity is more than 2.7 Million pieces.

120 automatic injection moulding machines are available, including FANUC injection machines imported from Japan

Injections are separated by checking and assembly, to ensure the assembling area is clean and has a constant temperature.

Intelligent Convey System, intelligent calling system, smart material management and smart tags are adopted

Glass Sourcing Support 玻璃配套

According to customers’ demands, Xinyu matches different glass product partners to obtain the best cost performance and ensure more than 99% quality for glass products.

With a complete high quality decoration process, Xinyu ensures the quality of finished glass.

Supporting various glass products, Xinyu delivers fitted parts of caps and pumps to ensure quantity and logistics synchronization with quality assurance

Intelligent Convey System, intelligent calling system, smart material management and smart tags are adopted

Spray & Metallization Workshop 涂装

Daily capacity is more than 1 Million pieces.

It is capable for auroral metallization, crystal process, ceramic spraying, light retaining and noctilucent, multi-curves ion coating, soft touch matte finish, UV spraying, vacuum metallizing, water-borne thermocuring spraying on various materials (glass, plastic, alumina).

Xinyu is China's first one to develop auroral metallization and has the largest production capacity for auroral metallization.

Xinyu owns invention patents for the crystal process and ceramic spraying

Printing Workshop 印烫

Daily capacity is more than 500,000 prints.

Auto silk screen printing machines, H/S machines and laser engraving machines are available.

Capable of silk screen printing, hot stamping, 3D decal application, shift printing, heat transfer printing and laser carving on various materials (glass, plastic, aluminium).

Assembly Workshop 装配

Daily capacity is more than 600,000 pieces.

40 assembly lines and more than 100 automatic assembly machines, as well as intelligent detection equipment, are available.

Production environment is clean and dust-free, with constant temperature and constant humidity.

By adopting an AI smart tag barcode system, all materials ensure traceability for each box and each batch with real-time reporting